Jewellery Technologie Service

Jewellery

Technology

Services

↓

Jewellery Technology Services

↓

At Patt Design we strive to make your jewellery design and production process more efficient by incorporating the right technologies and machines into your workflow. We help in determining your requirements to decide what technologies are necessary to improve your process.

After selecting the best machines, according to your needs, we install the machines and offer internal training and safety sessions to to get the most out of your new tech.

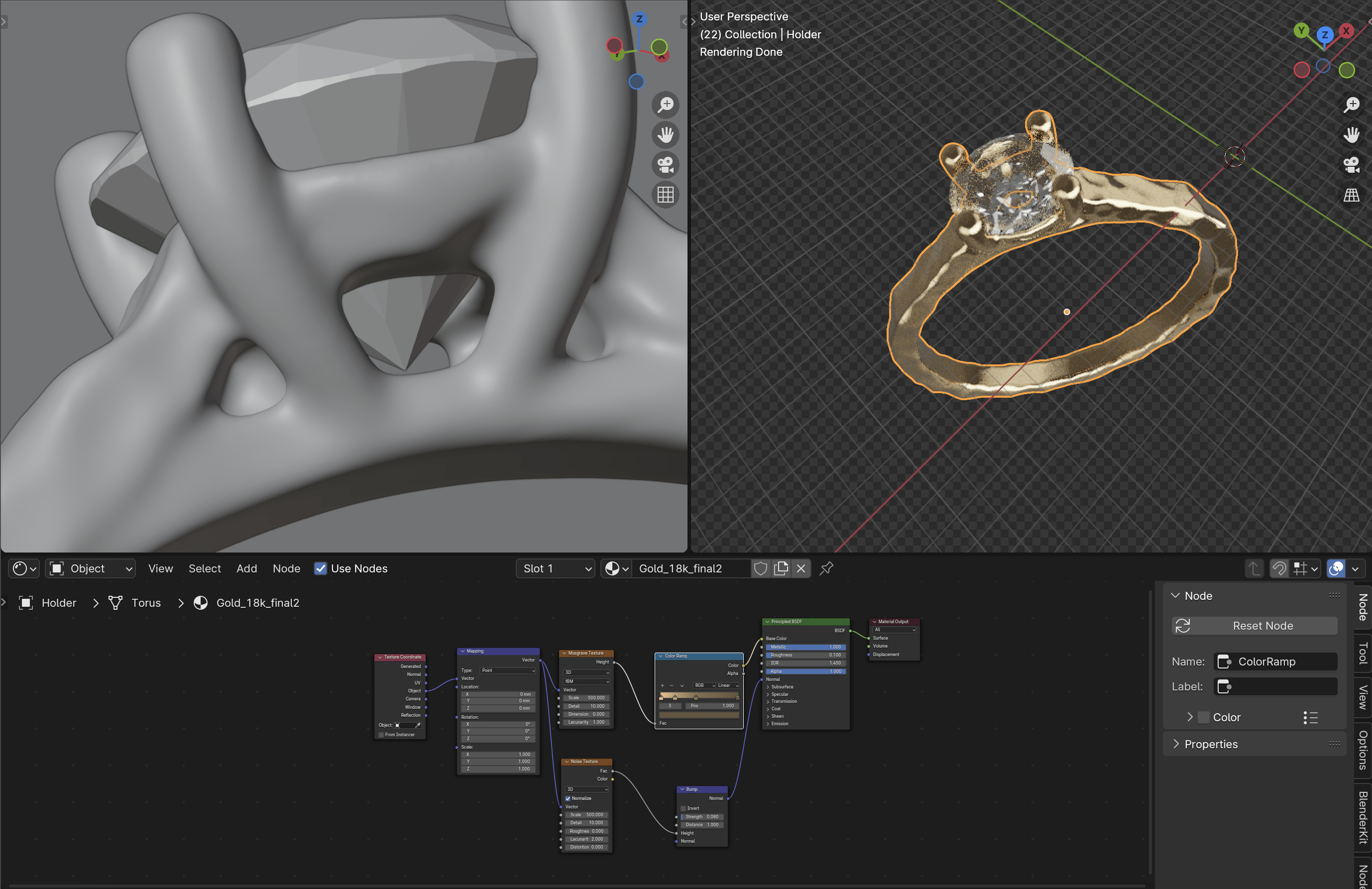

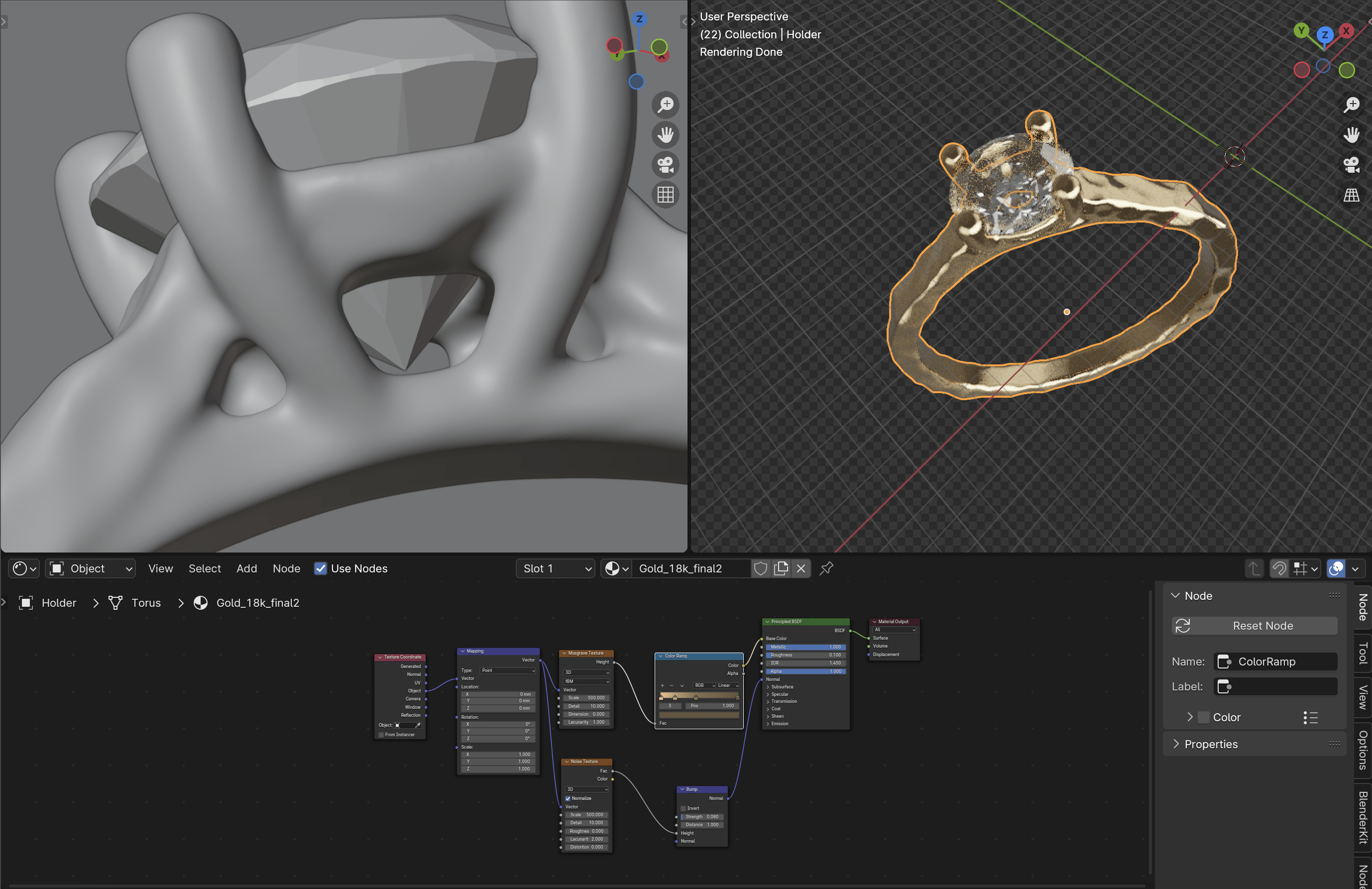

3D DESIGN - MODELLING AND RENDERING

Increase the efficiency and precision of your jewellery designing process by using 3D programs. The use of 3D design makes it possible to create highly detailed shapes and textures which are not possible by hand. The ring size of models can easily be adjusted and prepared for 3D printing which saves a lot of manual labour time. The implementation of 3D designing software in your workflow will significantly increase efficiency and decrease lead times.

3D SCANNING - SCAN AND ADJUST

Optimise your workflow by using state-of-the-art 3D scanning technology. Digitalise your manually crafted pieces to make adjustments or to resize the model. Scan separate components of the jewel and merge them in 3D. The use of 3D scanning makes it also possible to convert real world objects into wearable jewellery. Incorporate the best scanner for your needs and expand your design possibilities.

3D PRINTING - PRINT CASTING MOLDS

Print your 3D models in extremely high detail. The use of 3D printing technology makes it possible to produce multiple models at once which increases lead times. Use castable printing material to cast the pieces using the lost-wax technique. We help determining the best printer for your needs.

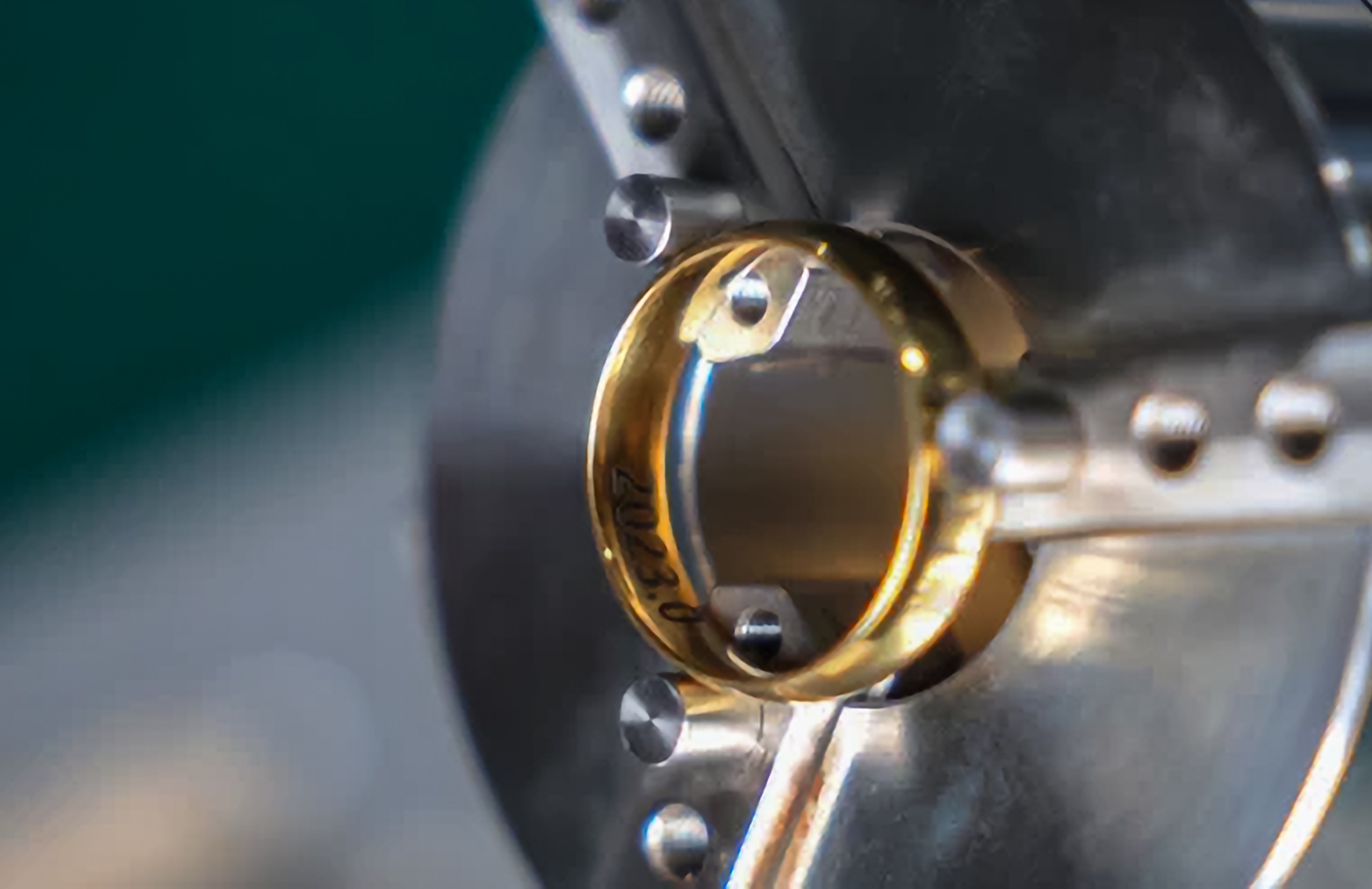

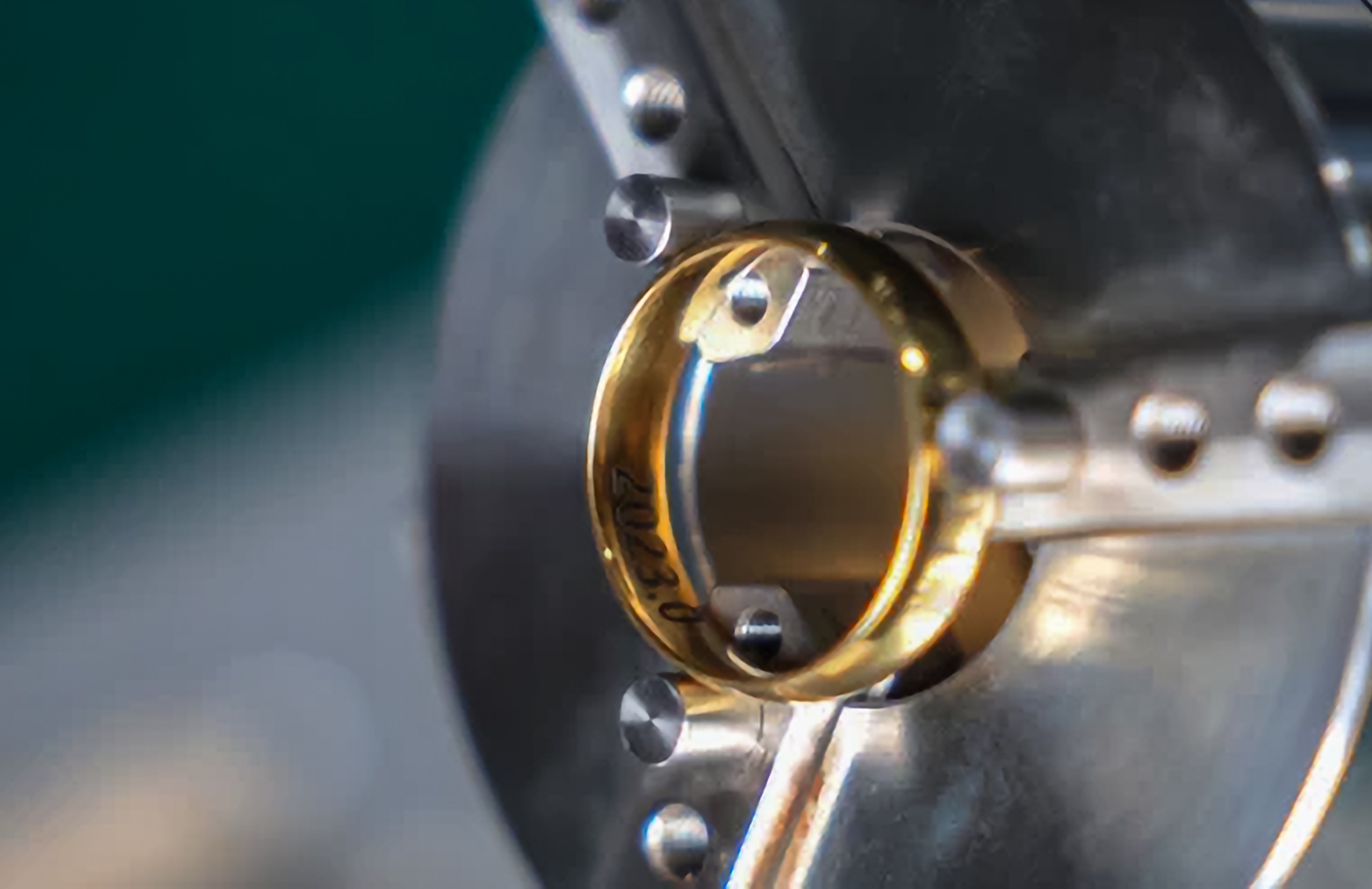

Laser engraving

Customise jewellery by using state-of-the-art engraving machines. Engrave gold, silver, brass and many more materials with laser engraving machines developed to engrave extremely high detail. Whether you want to engrave rings, bracelets or pendants, we determine the best machine for your needs.

3D DESIGN - MODELLING AND RENDERING

Increase the efficiency and precision of your jewellery designing process by using 3D programs. The use of 3D design makes it possible to create highly detailed shapes and textures which are not possible by hand. The ring size of models can easily be adjusted and prepared for 3D printing which saves a lot of manual labour time. The implementation of 3D designing software in your workflow will significantly increase efficiency and decrease lead times.

3D SCANNING - SCAN AND ADJUST

Optimise your workflow by using state-of-the-art 3D scanning technology. Digitalise your manually crafted pieces to make adjustments or to resize the model. Scan separate components of the jewel and merge them in 3D. The use of 3D scanning makes it also possible to convert real world objects into wearable jewellery. Incorporate the best scanner for your needs and expand your design possibilities.

3D PRINTING - PRINT CASTING MOLDS

Print your 3D models in extremely high detail. The use of 3D printing technology makes it possible to produce multiple models at once which increases lead times. Use castable printing material to cast the pieces using the lost-wax technique. We help determining the best printer for your needs.